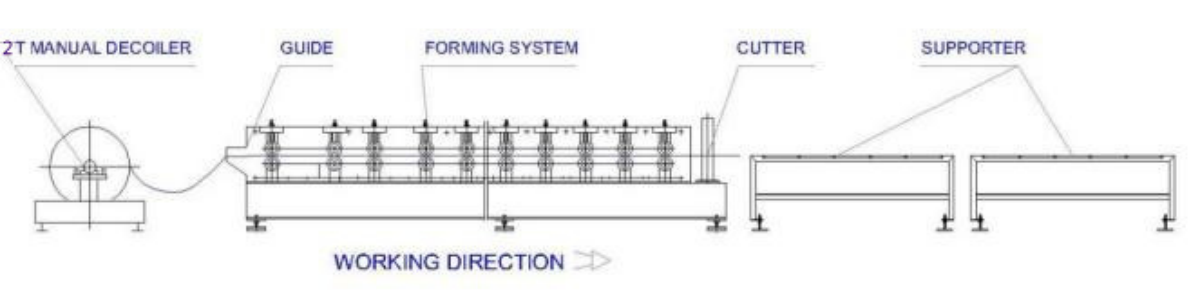

Metal Roofing Floor Deck Making Machine Galvanized Floor Decking Roll Forming Machine

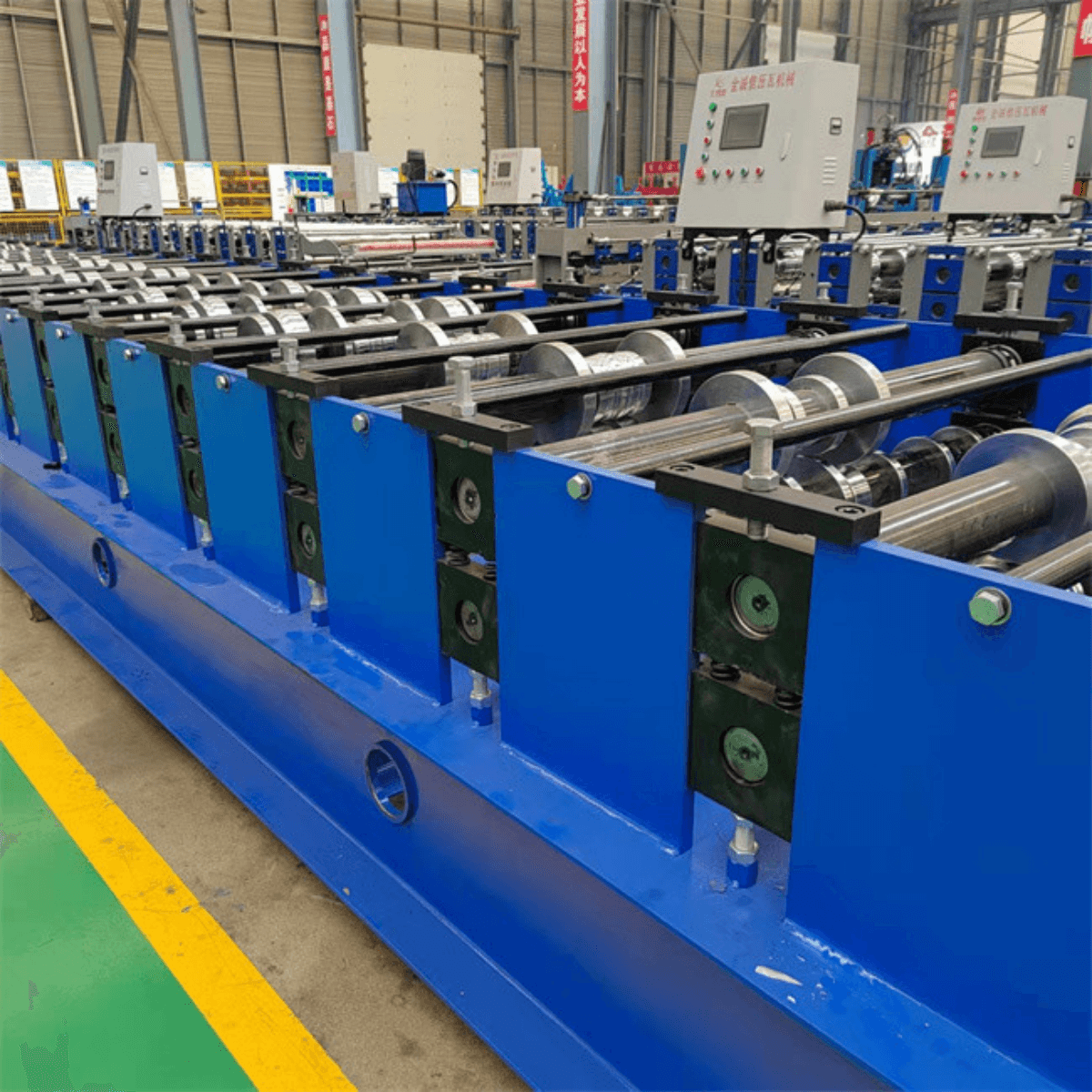

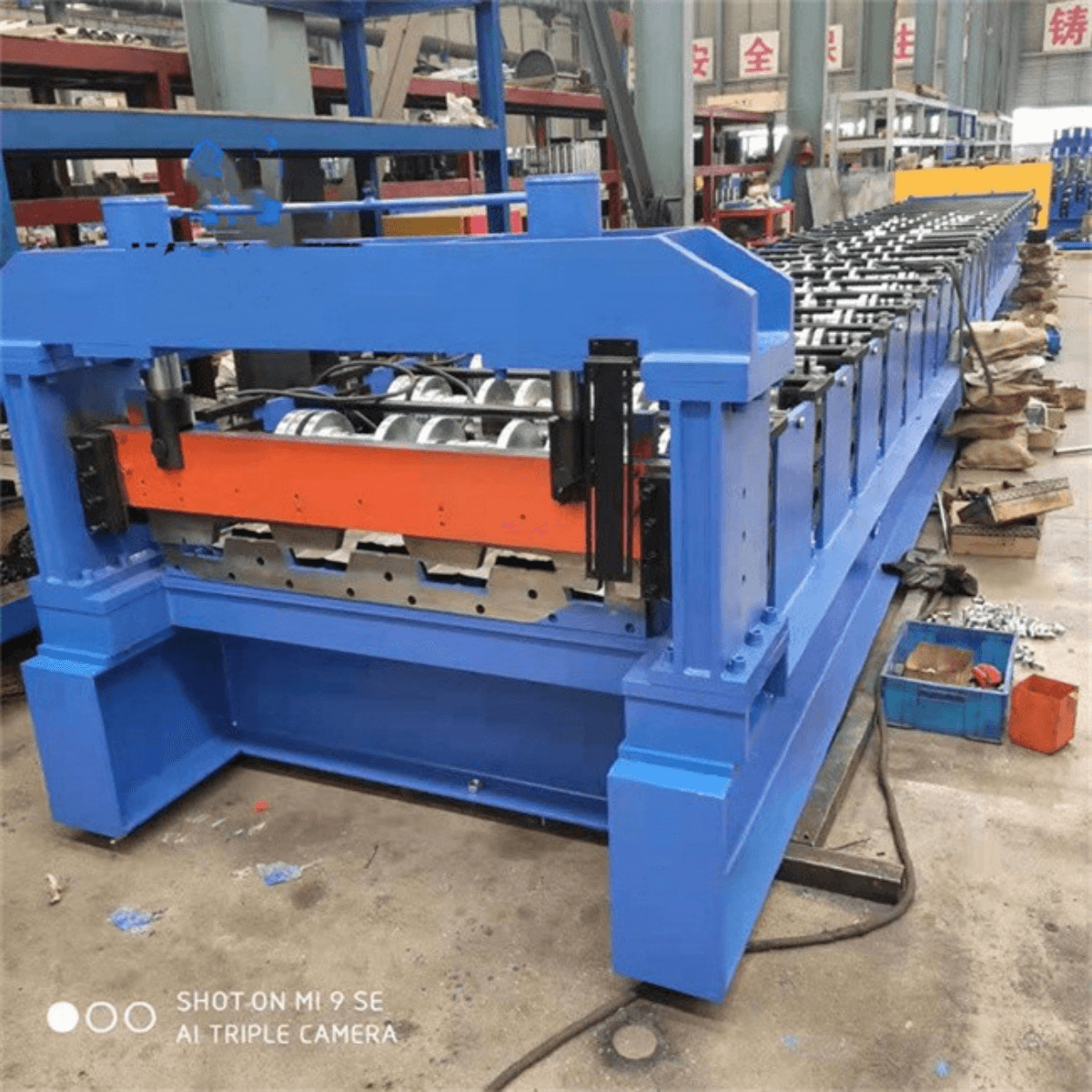

Machine Pictures

Description

The metal deck produced by floor decking roll forming line has high strength with big wave length. It adheres well to concrete. Used on high building, it not only saves steel mold plate, but also reduces the weight of storey. With the same bearing capacity, it economized steel and cuts down investment accordingly.

Our factory is manufacturing high quality floor decking roll forming machine, and regularly exported to Australia, USA, Thailand, Canada,Turkey, Indonesia, Philippines, Malaysia, India, Angola, etc.

Technical Details

|

floor decking roll forming Machine Specifications |

|

| Weight | About 12tons |

| Size | About 12.5mx1.5mx1.3m(length x width x height) |

| Color | Machine Main color: blue or can as your requirement |

| Warning color: yellow | |

|

Suitable Raw Material |

|

| Material | Galvanized Steel Coils,color steel |

| Thickness | 0.8-1.5mm |

| Yield Strength | 235Mpa |

|

Main Technical Parameters |

|

| Quantity of forming rollers stations | 25stations |

| Diameter of forming rollers shafts | 95mm |

| Roll Forming Speed | 15-20m/min |

| Forming rollers material | No.45 steel, coated with chromed treatment |

| Cutter material | CR12 mould steel, with quenched treatment |

| Controlling system | PLC and Converter |

| Electric Power requirement | Main motor power: 18.5kw+18.5kw |

| Hydraulic unit motor power: 5.5kw | |

| Electric voltage | According to customer’s requirement |

Main Components

|

Decoiler |

1 Set |

|

Guiding Equipment |

1 Set |

|

Roll Forming Unit |

1 Set |

|

Post Cutting Unit |

1 Set |

|

Hydraulic Station |

1 Set |

|

PLC Control System |

1 Set |

|

Reveiving Table |

1 Set |

Production Flows

Uncoiling the sheet---Infeed guiding--Roll forming---Rectifying the straightness---Measure length---Cutting the panel--panels to the supporter (option: automatic stacker)

Advantages

Our factory have 5 engineers with more than 20 years experience

We have 30 professional technician

we have 20 sets advanced CNC production lines to produce the machine rollers

We have professional designers and professional training,and have professional equipment, in this case we can provide professional machines.

We are very rigorous in every tiny detail,including raw material and making machines.

Application

This machine is widely used in the production of the roof and floor systems.

Product Photo

Product photo

Q. Why are your prices higher than others?

Because we insist that every factory should put quality first, we make the machines more automated, more reliable and accurate, and have a longer service life. The equipment can be used for nearly 20 years, and we provide lifetime after-sales service.