Red Color Photovoltaic bracket Roll Forming Machine PLC Control Full Automatic

Red Color Photovoltaic bracket Roll Forming Machine PLC Control Full Automatic

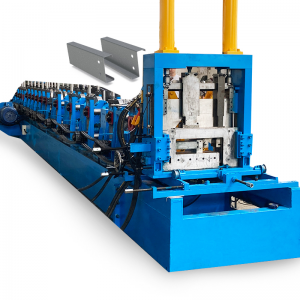

1. Machine Description

This machine is special equipment for rolling metal/steel coils, processing with decoiling,continuously feeding – punching – roll forming, automatic length/quantity to cut for customer’s request. Whole unit with PLC control,AC variable frequency speed regulation technology for automatic solar unistrut production, that would be the ideal equipment for cold steel roll forming and steel structure.

2. Machine picture of solar panel support roll forming machine

3. Supplying components of complete machine

NO. Description Quantity (set) Remark

1 Manual Decoiler 3 Ton 1

2 Guiding device 1 One complete unit as main machine

3 Forming system 1

4 Transmission system 1

5 Flying Saw Cut 1

6 Support table 2

7 Hydraulic station 1

8 Control box 1

9 Spare parts and tools 1 As attaching list

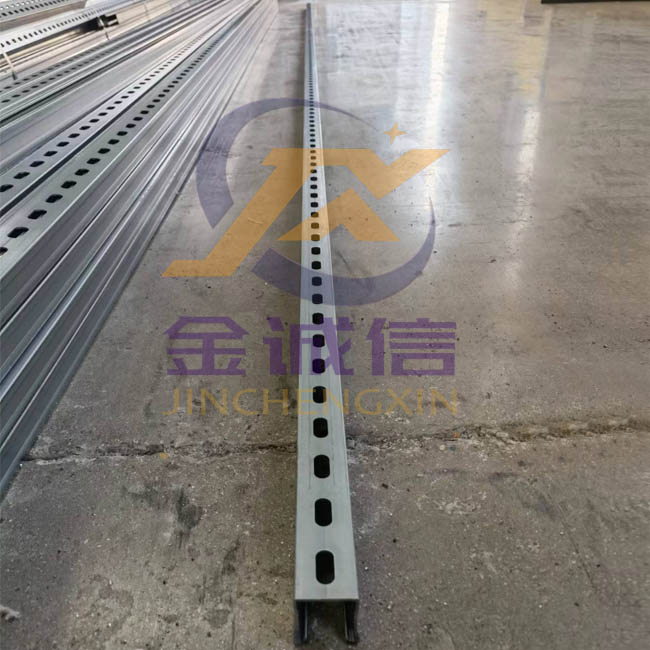

4. Detailed Images of solar panel support roll forming machine

Weight

About 12.5 tons

Size

About 17*1.5*1.5m(length x width x height)

Color

Main color: blue or as your requirement

Warning color: yellow

Material

zinc magnesium aluminum, galvanized sheet ,black belt

Thickness

2.0 mm

Yield Strength

235Mpa

Quantity of forming rollers stations

18

Diameter of forming rollers shafts

80mm

Roll Forming Speed

15-23m/min

Forming rollers material

No.45 steel, coated with chromed treatment

Cutter material

Cr12MoV steel, with quenched treatment

Controlling system

PLC and Converter

Electric Power requirement

Main motor power: double 15kw hydraulic motor

Electric voltage

According to customer’s requirement

5.Packing and delivery

6. Our Company Introduction

Our machine can produce the Photovoltaic bracket ,roof panel, wall panel ,sandwich panel , floor deck panel, decoration buckles, light-gauge steel joists, shelf columns, door frame parts and other profiled accessories. It has the advantages such as high production efficiency, stable product sizes, less investments, etc.

Company according to the different industry use produce the different profiled accessory roll forming machines. It is widely used in the areas such as construction decorations, doors manufacturing, shelf fabrication, logistics, etc.

our factory is manufacturing high quality storage rack roll forming machines, and exported to the foreign countries such as Lebanon, Iran, Jordan, France, United Kingdom,Australia, Malaysia, Indonesia, Vietnam, Thailand, Russia, Saudi Arabia, Singapore, etc.

7. FAQ

1. Does one machine can only produce one style panel profile?

Not exactly.For wider and double layer making machine. It can produce more than 6 kinds of panels.

2. Do you have after sales support?

Yes, we are happy to give advice and we also have skilled technicians available across the world.We need your machines running in order to keep

your business running.

3. How to visit your company?

a.Fly to Beijing airport: By high speed train From Beijing Nan to CangZhou Xi (1 hour), then we can pick up you.

b.Fly to Shanghai Airport: By high speed train From Shanghai HongQiao to Cangzhou Xi(4.5 hours), then we can pick up you.

4. What can you do if the machine broken?

Our machine’s warranty period is 24months,if the broken parts can’t repair,we can send the new parts replace the broken parts freely,but you need

pay the express cost yourself.if after warranty period,we can through negotiation for to solve the problems,and we supply the technical support for

the whole life of the equipment.

5. Can you be responsible for transport?

Yes,please tell me the destination port or address.we have rich experience in transport.

6. Why your price is higher than others?

As we persist on that each factory should put quality at the first place. We spend time and money on developing how to make machines much more automatic, accurate and high quality.

.