380V 50Hz Blue Metal Deck Roll Forming Machine 8-10m/min High Working Speed

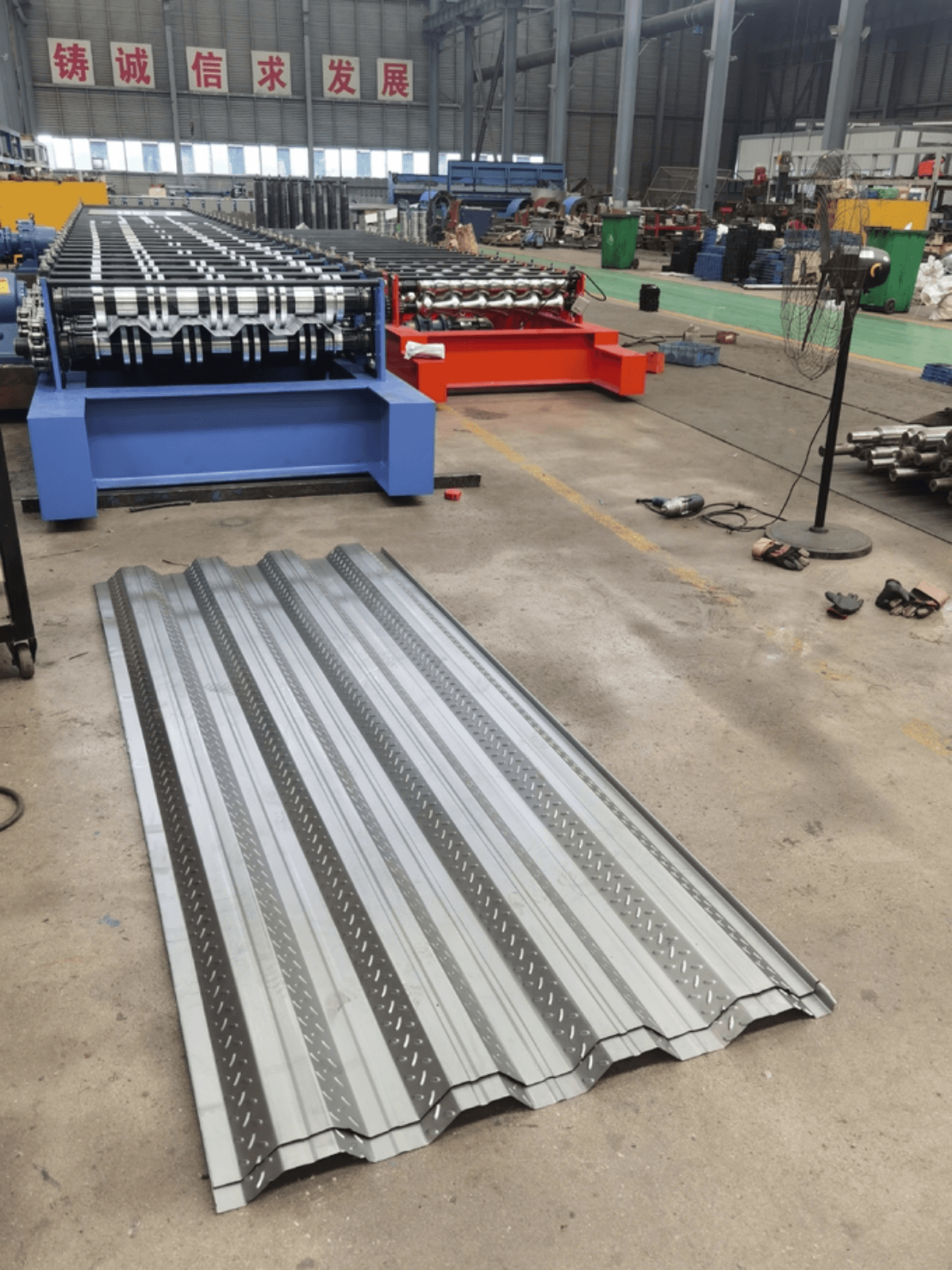

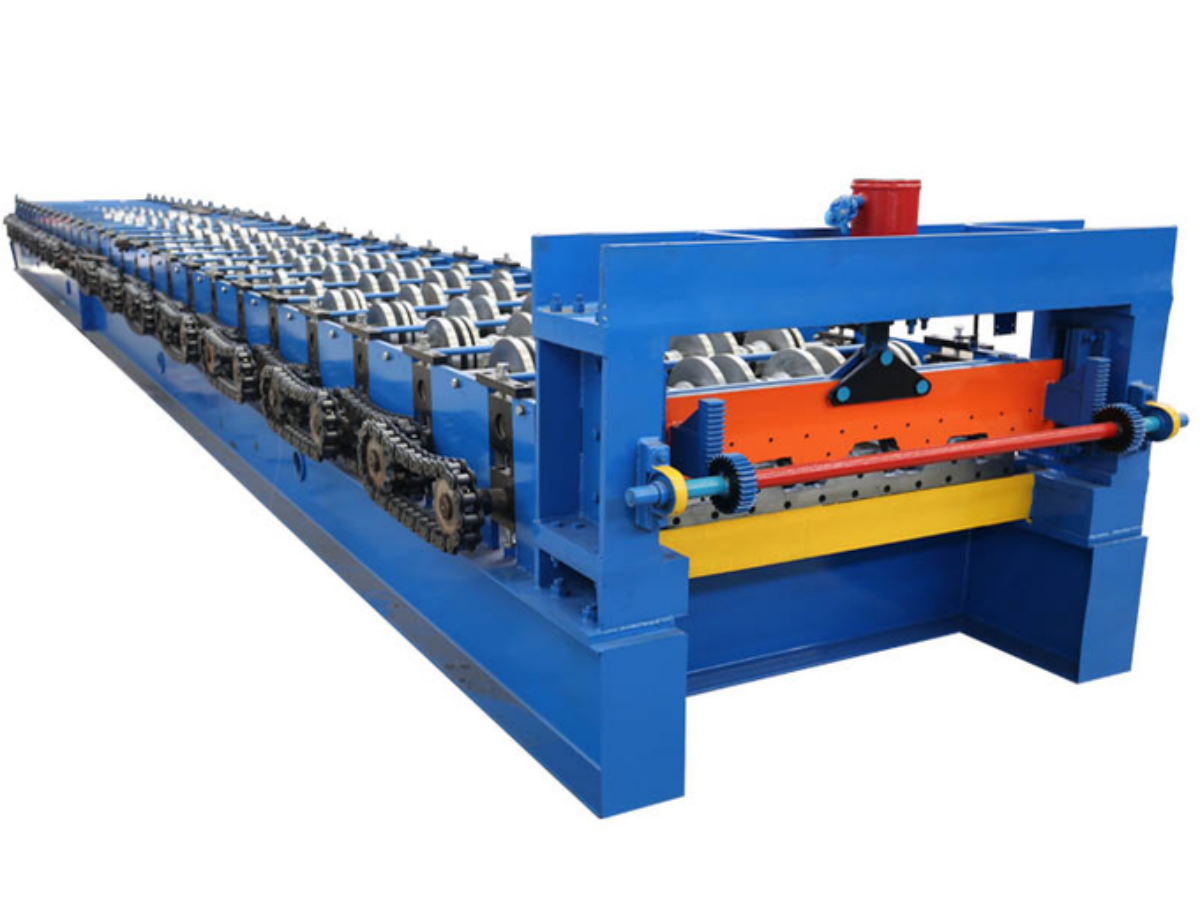

Machine Pictures

Description

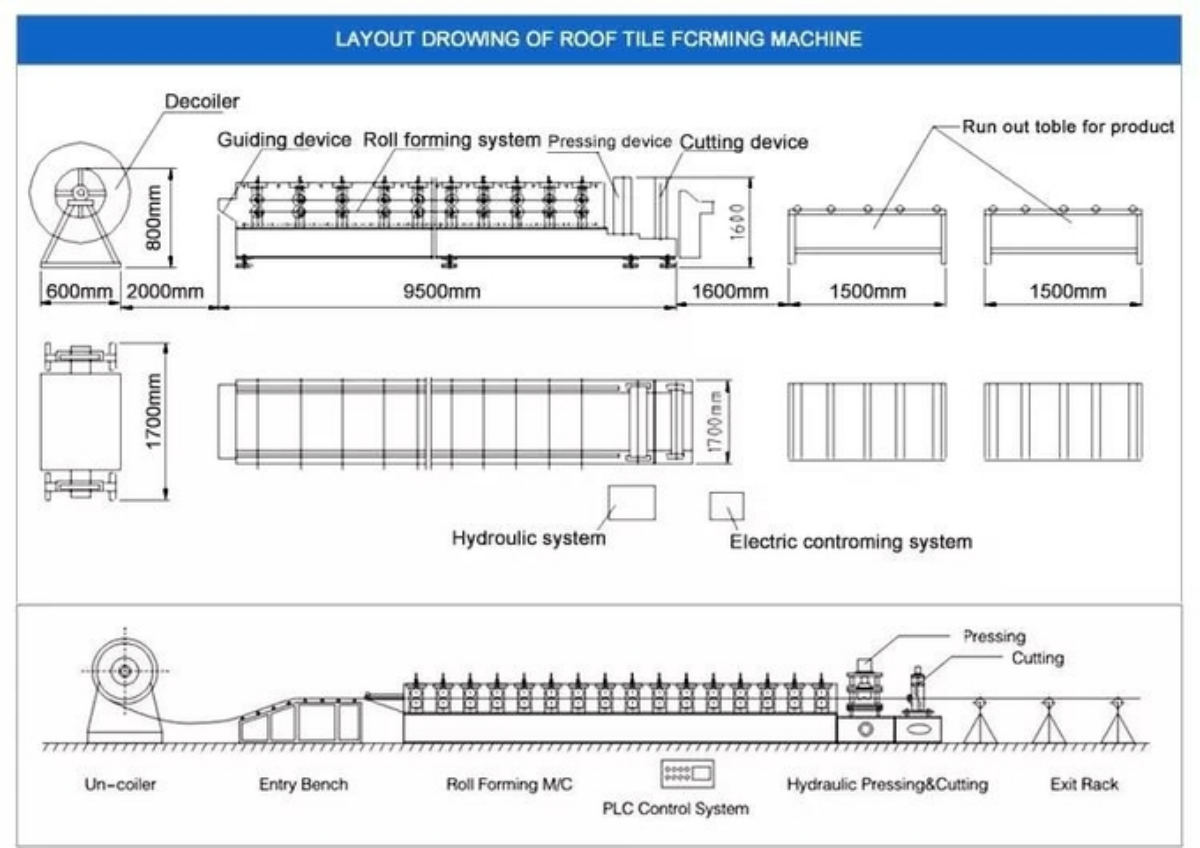

A metal deck or steel deck roll forming machine consists of a 5TON manual de-coiler, feeding guide, an electrical entry shearing with 0.75KW motor power,a roll forming part including an embossing tools, transmission system, hydraulic system, a PLC control cabinet, a hydraulic oil pump and runout tables to support the final products.

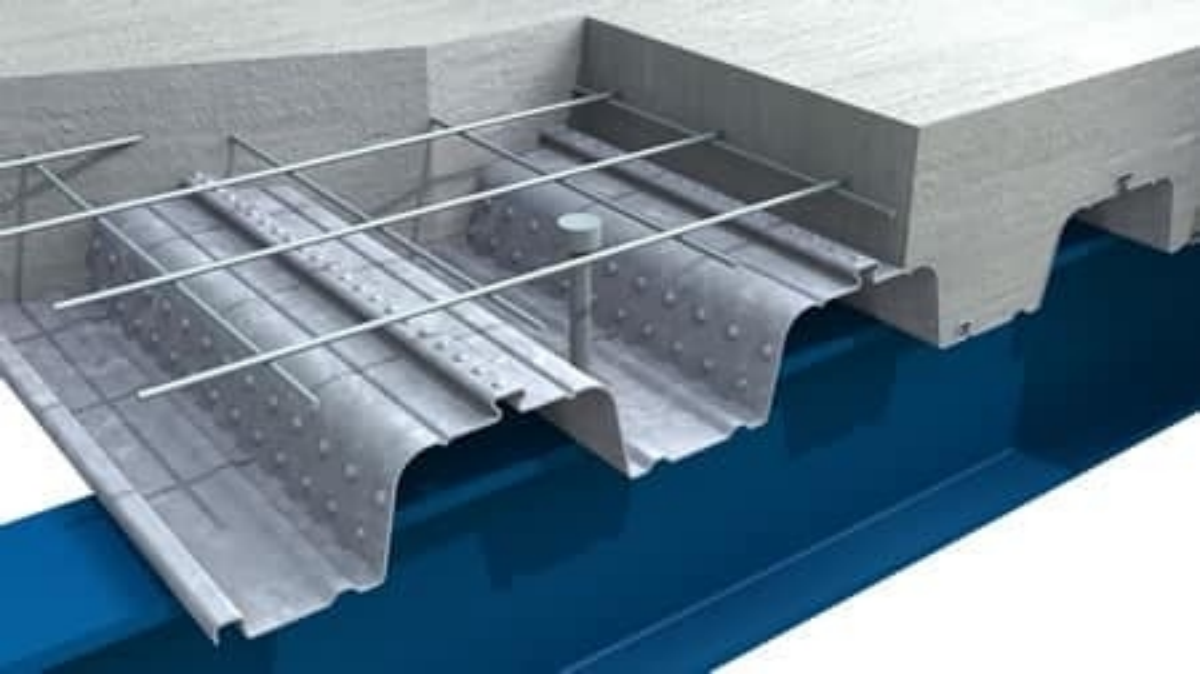

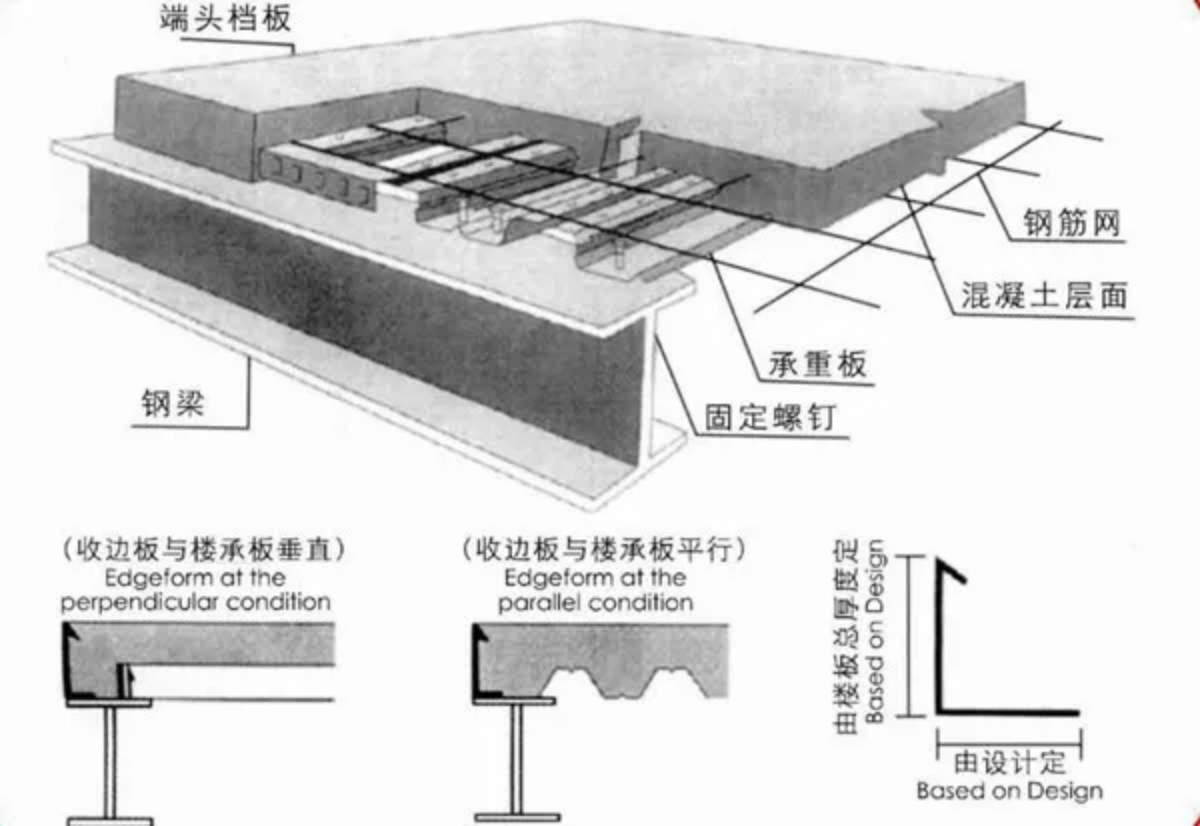

This roll forming machine can roll forming metal floor decking panel profile. After roll formed by this roll forming machine, the surface will be very smooth and beautiful without any scratch on surface. The designing of metal deck forming machine is aided and optimized by computer. The metal deck produced by this machine has high strength with big wavelength. It adheres well to concrete. Used on high buildings, it not only saves steel mold plate, but also reduced the weight of storey. With the same bearing capacity, it economizes steel and cuts down investment accordingly.

Technical Details

| Axis Diameter | 85 mm |

| Pre-cutting unit | Hydraulic way |

| Forming Roller station | 22 groups |

| Main Axis material | First grade 45# steel |

| Forming Speed | 12-13m/min |

| Cutting system power | 7.5KW |

| Cutting length tolerance | ±0.05mm |

| Voltage | 380V/50Hz/3P |

Main Components

| No. | Name | Unit | Qty |

| 1 | Decoiler | set | 1 |

| 2 | Entry Beach | set | 1 |

| 3 | Main Machine for roll forming | set | 1 |

| 4 | Cutting System | set | 1 |

| 5 | Output Table | set | 1 |

| 6 | Control System(PLC) | set | 1 |

| 7 | hydraulic station | set | 1 |

Production Flows

Uncoiling the sheet---Infeed guiding--Roll forming---Rectifying the straightness---Measure length---Cutting the panel--panels to the supporter (option: automatic stacker)

Advantages

· Germany COPRA software design

· 5 engineers with more than 20 years experience

· 30 professional technician

· 20 sets advanced CNC production lines on site

· Passionate Team

· Installation engineers can reach your factory within 6 days

· 1.5 years maintenance and whole life technical support

Application

The advantage of glazed steel sheet includes beautiful, classical appearance and grace taste. It is widely used in village, hotel, exhibition, vacation village, family construction and outdoor decorating.

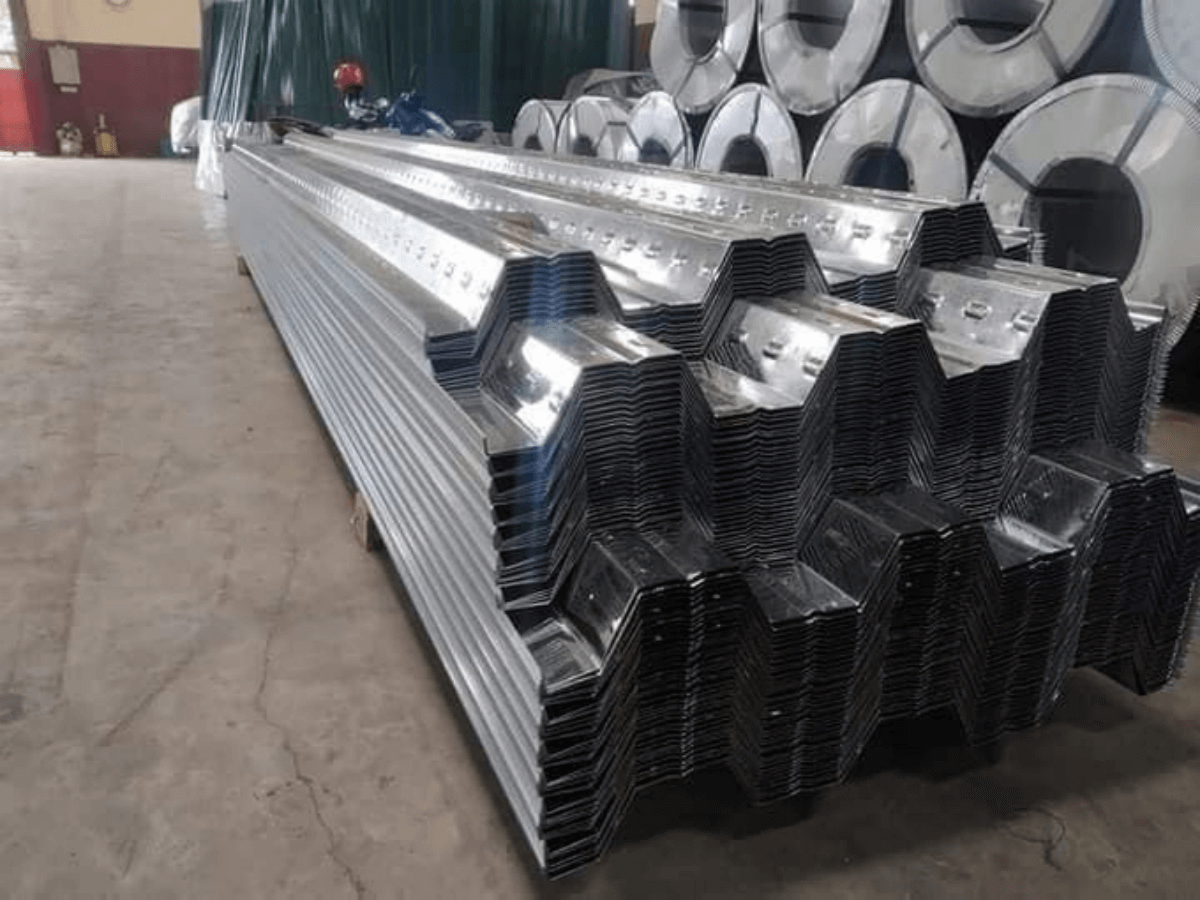

Product Photo

FAQ

1. Who are we?

We are based in Hebie, China, start from 2010, sell to Africa(20.00%), Domestic Market(20.00%), Southeast Asia(15.00%), South America(10.00%), North America(5.00%), Eastern Europe(5.00%), Oceania(5.00%), Mid East(5.00%), Central America(5.00%), South Asia(5.00%), Eastern Asia(2.00%), Western Europe(2.00%), Southern Europe(00.00%). There are total about 51-100 people in our office.

2. How can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3. What can you buy from us?

Roof Sheet Roll Forming Machine, Wall Panel Roll Forming Machine, Highway Guardrail Plate Forming Machine, Floor Decking Sheet Rolling Machine, C Purlin Making Machine.

4. Why should you buy from us not from other suppliers?

1. Rich experience

2. High-quality after-sales service system

3. Brand and Qualification Guarantee

4. Technological innovation advantage.

5. What services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,FAS,CIP,FCA,CPT,DEQ,DDP,DDU,Express Delivery,DAF,DES;

Accepted Payment Currency:USD,EUR,JPY,CAD,AUD,HKD,GBP,CNY,CHF;

Accepted Payment Type: T/T,L/C,D/P D/A,MoneyGram,Credit Card,PayPal,Western Union,Cash,Escrow;

Language Spoken: English, Chinese, Spanish, Japanese, Portuguese, German, Arabic, French, Russian, Korean, Hindi, Italian.