Supply OEM Zhongde Glazed Tile Roll Forming Machine Roof Tile Making Machine for Tile Making

We have been commitment to offer the aggressive value ,exceptional goods good quality, likewise as fast delivery for Supply OEM Zhongde Glazed Tile Roll Forming Machine Roof Tile Making Machine for Tile Making, We promise to try our greatest to deliver you with high quality and economical products and services.

We have been commitment to offer the aggressive value ,exceptional goods good quality, likewise as fast delivery for China Roll Forming Machine and Roof Roll Forming Machine, In the new century, we promote our enterprise spirit “United, diligent, high efficiency, innovation”, and stick to our policy”basing on quality, be enterprising, striking for first class brand”. We would take this golden opportunity to create bright future.

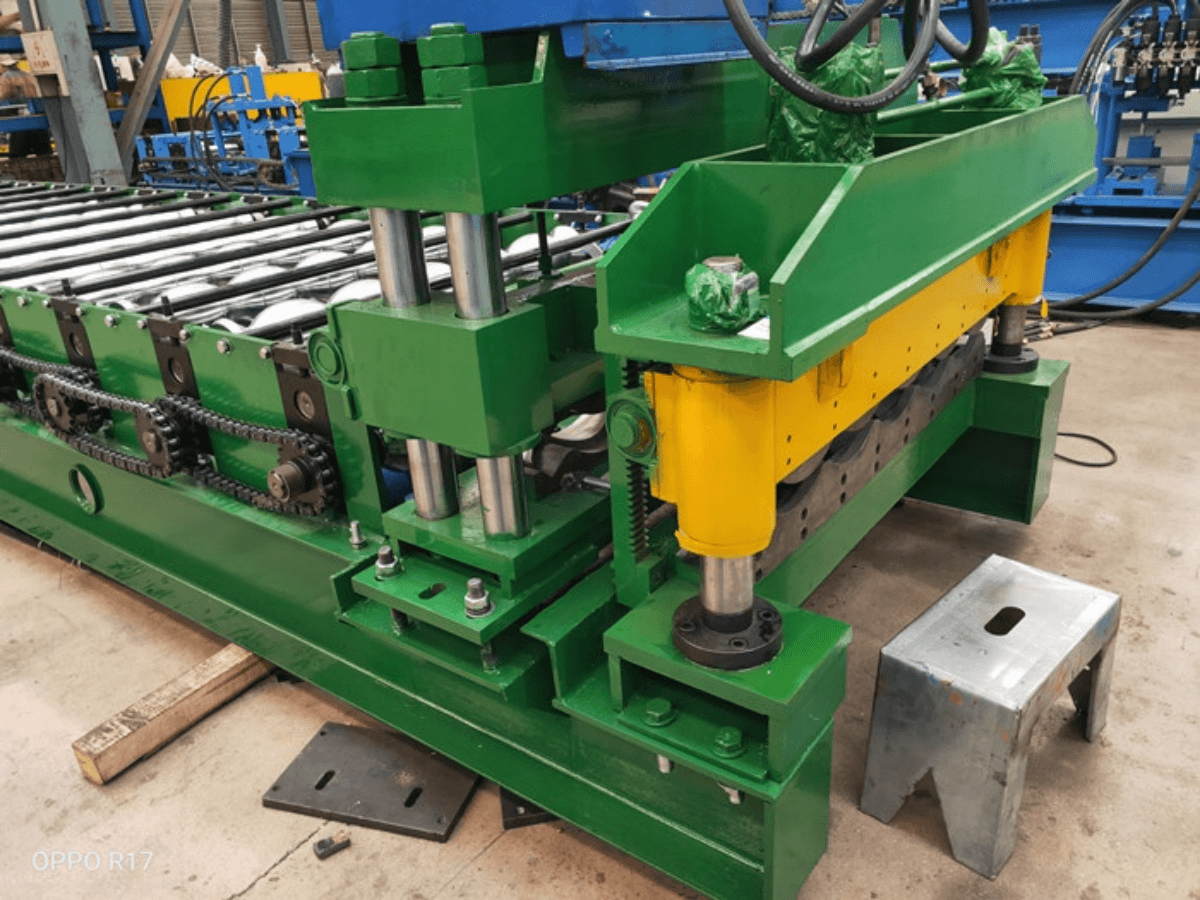

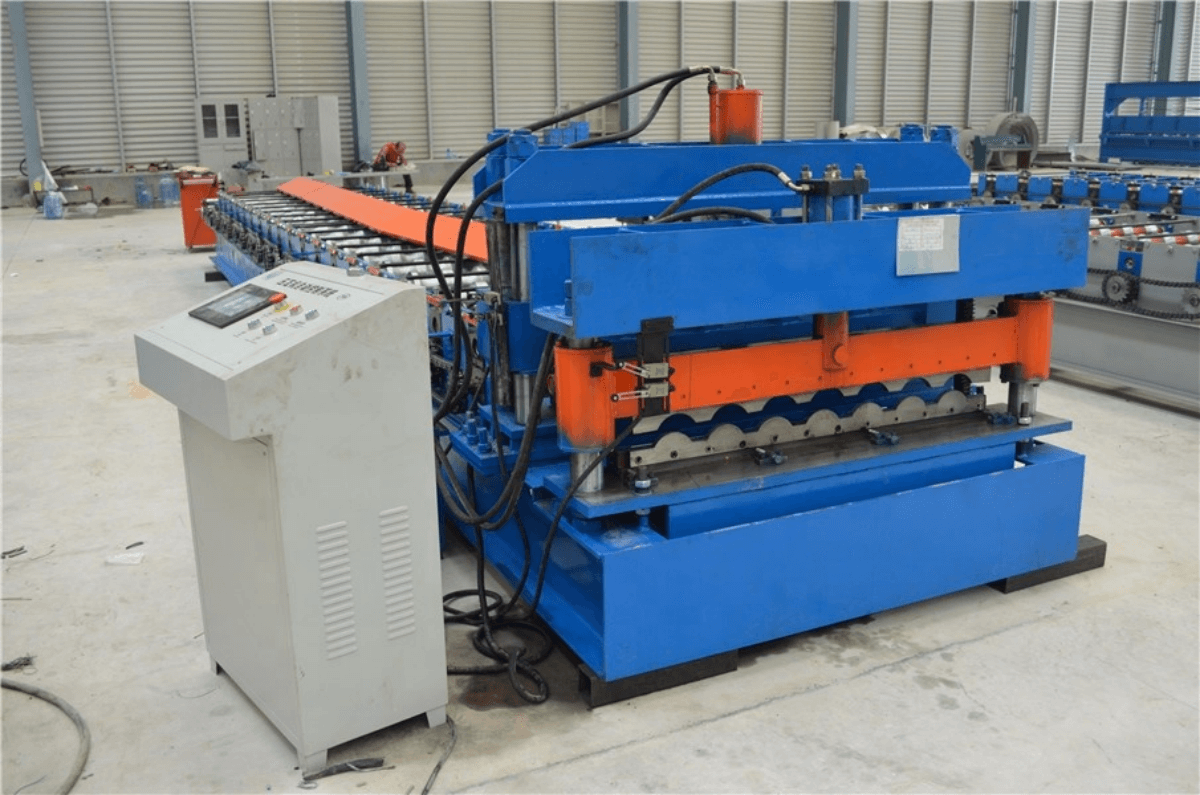

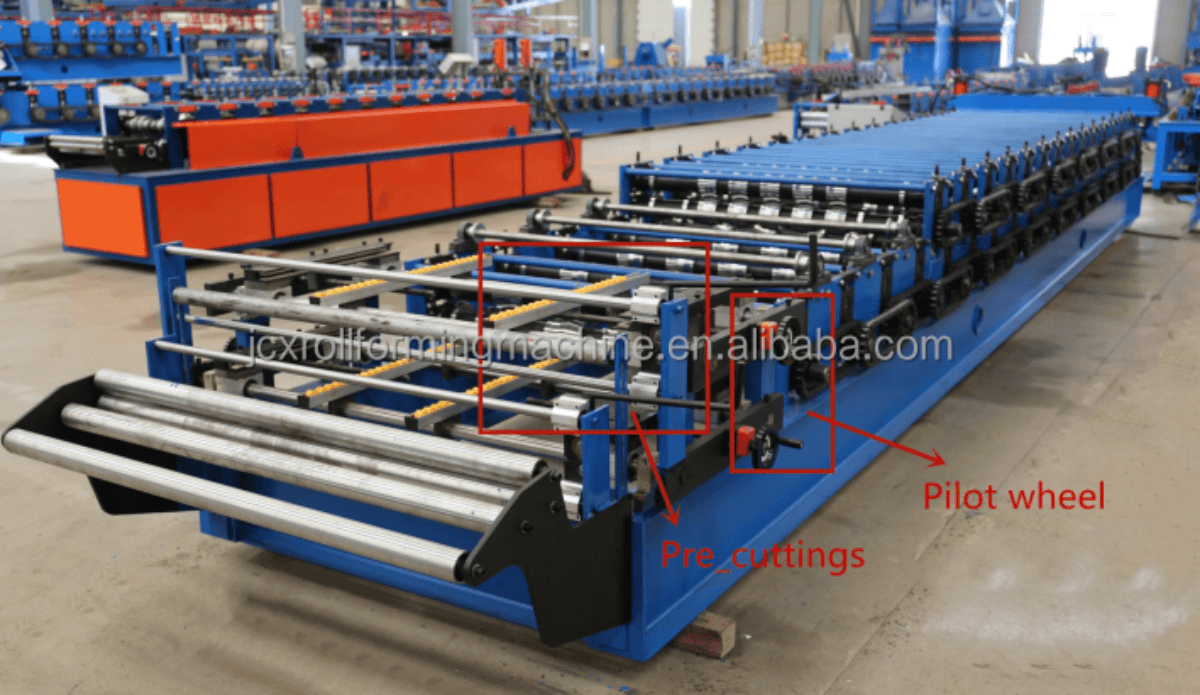

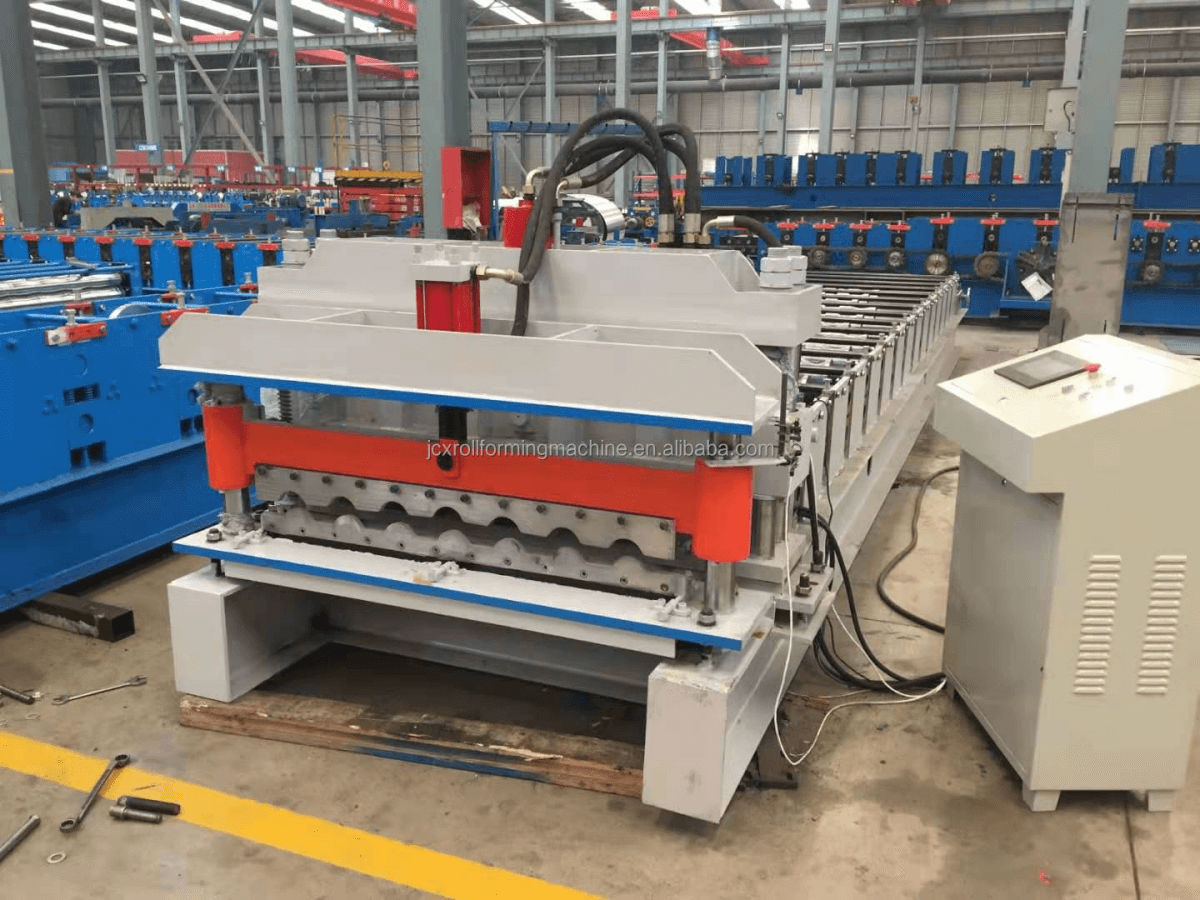

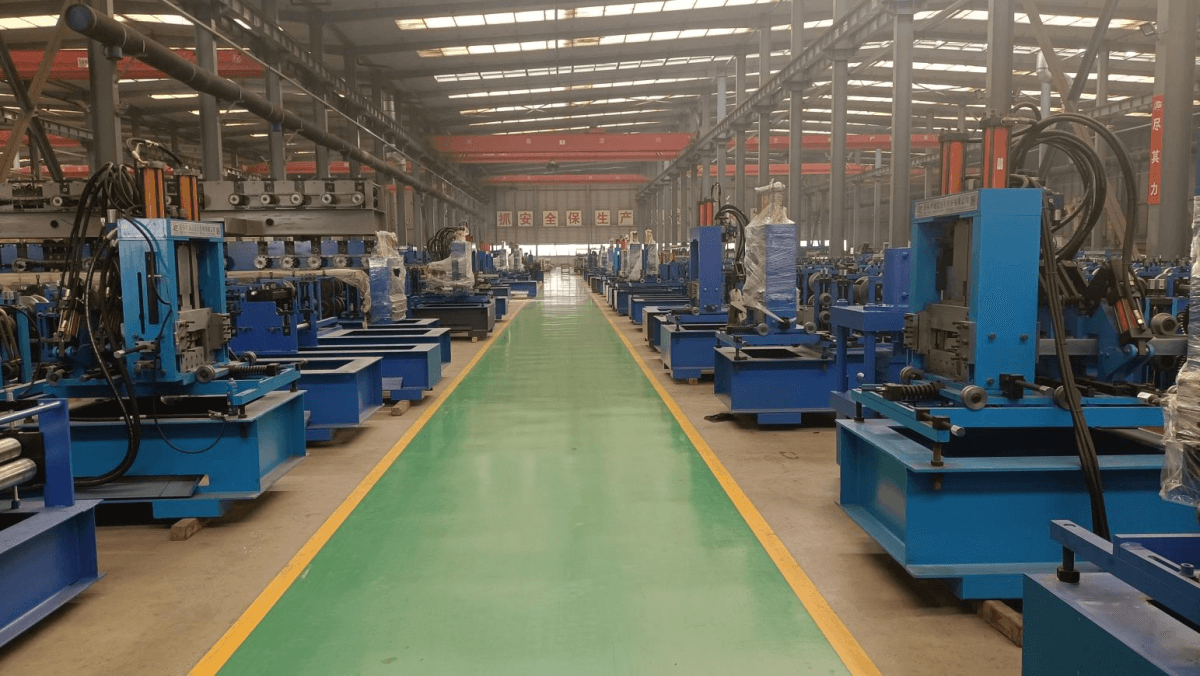

Machine Pictures

Specification

| No | Item | Parameter |

| 1 | Decoiler | 5tons electric decoiler (Hydraulic decoiler optional), manual one free |

| 2 | Forming speed | 12-18m/min |

| 3 | Material | G235grade steel or galvanized coil |

| 4 | Thickness | 0.3-0.7mm |

| 5 | Forming steps | 14 +13forming steps |

| 6 | Shaft | Diameter 75mm, all solid |

| 7 | Rollers | High grade 45# steel with heat treatment and hard chrome coating 0.04-0.05 |

| 8 | Main frame system | H350 steel. By blasting |

| 9 | Motor brand | shanghai lichao motor |

| 10 | Main forming power | 5.5kw. |

| 11 | Pump Station Power | 4Kw, or electric cutting for 3kw |

| 12 | Cutting Type | hydraulic cutting or electric cutting |

| 13 | Cutting Blade | Cr12Mov with hard treatment, HRC52-68 |

| 14 | Control System | Delta PLC, Touch screen, Frequency converter |

| 15 | Measuring accuracy | Precision +/-1.5mm,with frequency converter |

| 16 | Transmission | By single chain 1’ |

| 17 | Machine Dimensions | About 7.5*1.5*1.7m |

| 18 | Machine weight | About 5500 kgs |

| 19 | Voltage | 380V,50hz, 3phase, as per request |

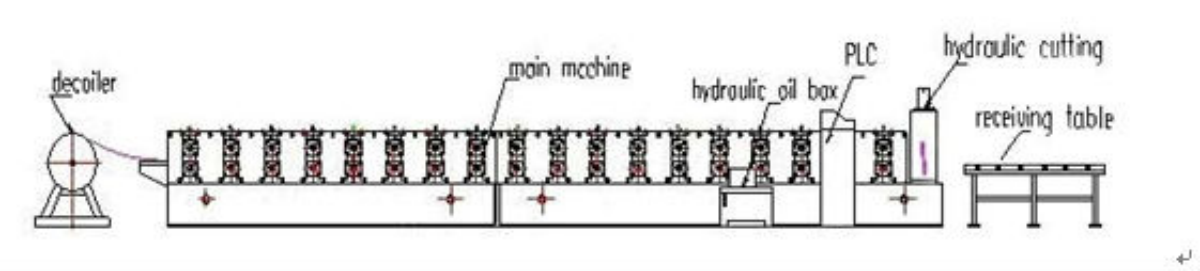

MACHINE COMPONENT

Decoiler

1. Capacity: it bears 5tons .

2. Material coil inner diameter: 450mm-550mm

3. Max width: 1250mm

Guiding Device

1. Advanced guiding device, ensure the steel roll in correct direction.

Main Forming Machine

Refer to machine parameters

Hydraulic Cutting

Hydraulic cutting system–Guide pillar type or Electric cutting. Speed more faster

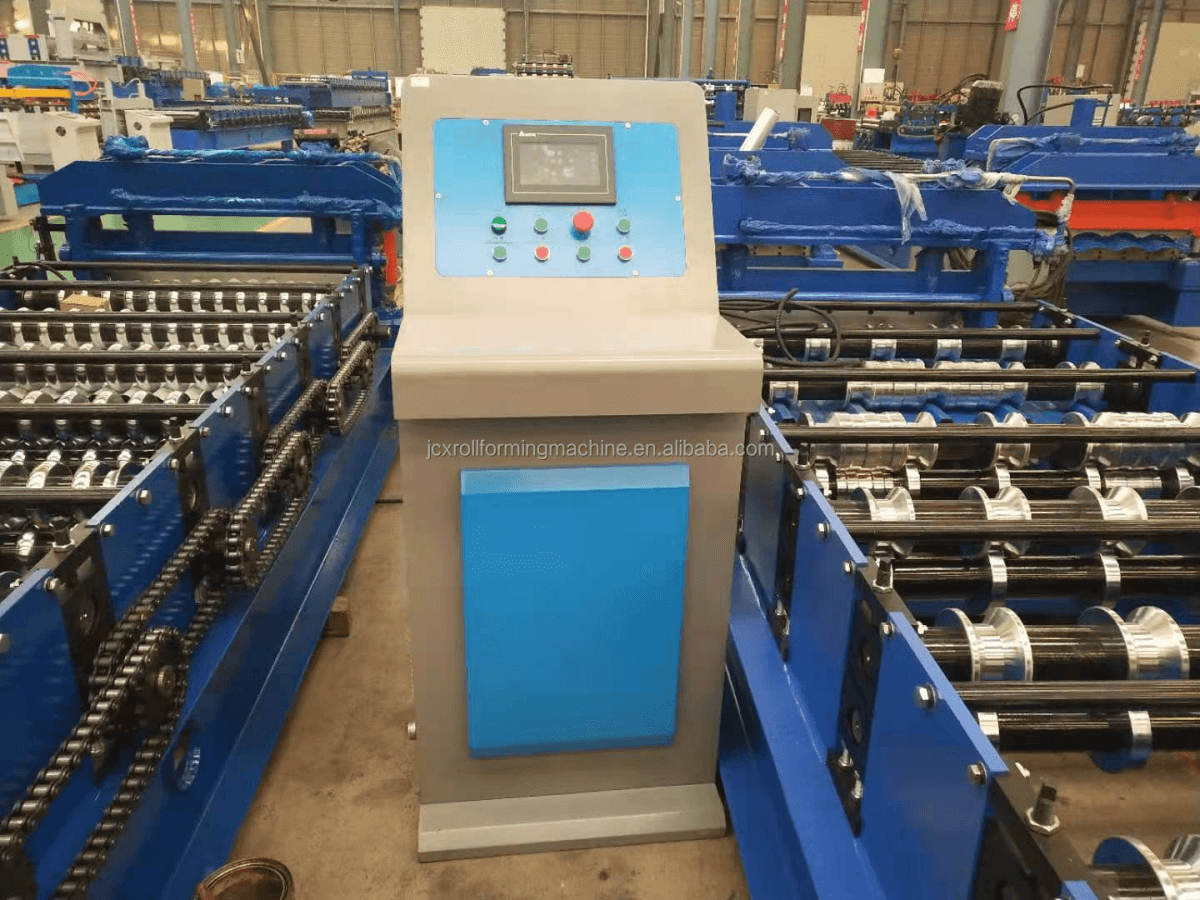

Control system

1). Screen:Delta

2). PLC: Delta

3). Automatic length measurement

4). Automatic quantity measurement

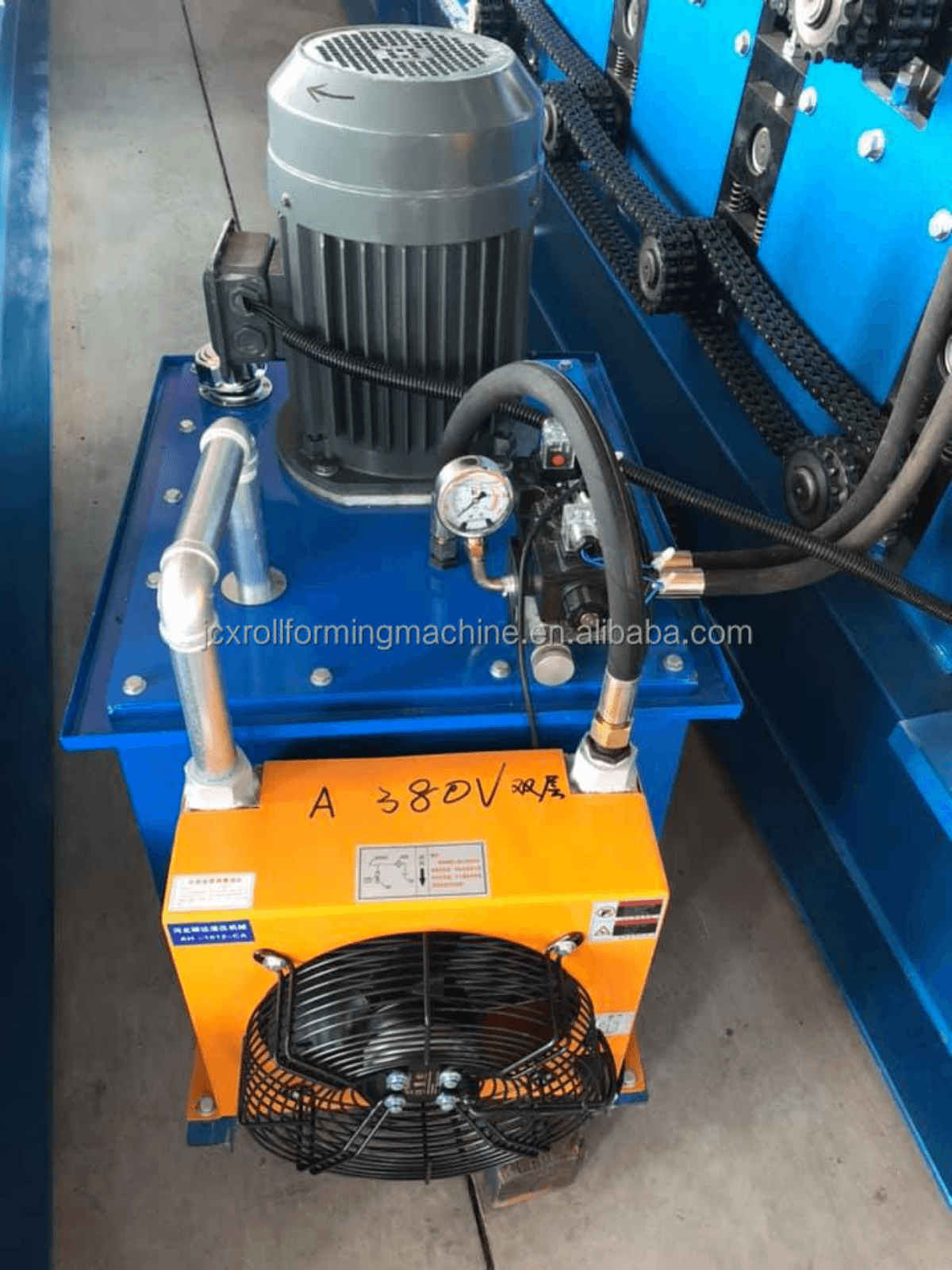

Hydraulic Station

1). Adopt advanced hydraulic system , with cooling fan.

2). Motor:4kw

3). Hydraulic oil: 46#

Packing & Delivery

1.One machine can be loaded in one 40GP container.

2.All machines will be tested before delivery

3.We will send manual book and operating video with the machines to you.

4.All spare parts will be packed in one tool box.

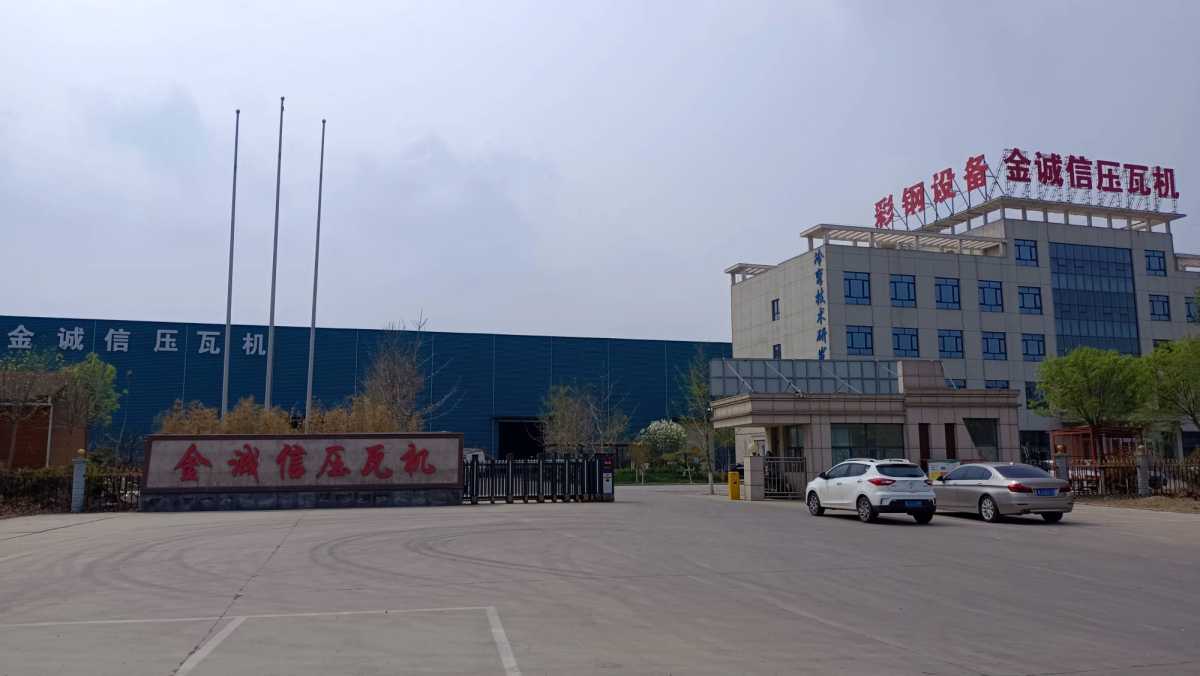

Company Profile

Botou Golden Integrity Roll Forming Machine Factory is located in “the town of casting molds”, enjoying convenient and highly effective transportation for being close to Tianjin Port, No.104 National Way, No.106 National Way and Jingjiu Railway. On the basis of traditional roll forming machines, we also develop new computer fully automatic roll forming machines, roof and wall panel forming machines, glazed tile forming machines, floor bearing plate forming machines, high-speed barrier devices, double color steel tile molding machines, C and Z steel machines, arch appliances, sandwich composite plate machines, shearing machines, bending machines, and heat insulation sandwich composite machines. Our products have reached the advanced level in the same industry. As beautiful appearance, reasonable structure, and tile-based standards of our products, they are popular among new and old customers. Products are sold to domestic enterprises.

FAQ

1. Does your company can customized my needed profile?

Yes sir/Madam. Our machines are all customized according to customers’ requests. Just provided me your needed profile drawing and we can give you our professional machine design solution.

2. If i don’t have profile drawing, but i want to buy one machine, can you help me?

Yes sir/ Madam. If you don’t have profile drawings, the solutions have:

2.1 : Provide me with your profiles’ pictures ;

2.2 : Tell me your country and i will check if we sell similar / related profile machines to your there. I will recommend you

related profile drawings.

2.3 : Tell me any information you have and it will be helpful for me to clear your needed profiles. and then quote you.

3. What your company advantages?

Yes sir/Madam. Our advantages have :

3.1: We are a 16 years big factory. We have abundant machine designing and making experience. We can give you the best

machine solution.

3.2: We have completed production system. And more than 20 sets of CNC machines which can support lots of machine

orders’ making and guarantee the delivery.

3.3 : We have 20 years foreign trade exported experience. Our sellers abundant experience can guarantee you will have a

pleasant purchase and use of the machine and after-sales experience. And cooperated with us , you can get more details about the machine, including those problems that you can’t think of but we can think of, we can tell you to ensure that you can buy the most suitable machine for you.

3.4 : We are a golden integrity roll forming machine company. About the after-sale services, no worries, we will responsible for you.

4. Will i receive a good machine ? Same with my wanted ?

Yes sir/Madam. We will do the machine according to your profile drawing . About the profile drawing, we will confirm with you again before producing your machine. Then, after the machine finished, we will test the machine and guarantee the machine you received is a good machine. Because after you satisfied with the machine, and then you pay balance.

5. What is the machine minimum quantity?

One machine is okay.

6. What is your payment terms?

6.1: We accept 30% T/T as deposit and 70% T/T as balance before shipping.

6.2: We accept 100% L/C at sight

6.3: We accept Western Union payments.

6.4: Other payment terms you want to pay, please let me know and i will check and reply you.

Stable Transmission Roof Tile Manufacturing Machine 8-12m/Min Forming Speed

1. Description of glazed tile roll forming machine:

The glazed tile roofing sheet is a new type of building material that replace the classic glazed tiles now. This machine cutting blade is made of Cr12 molybdenum with high hardness and good wear resistance. This machine is very beautifull. The typical application of this roll forming machine is on the roof or wall of a steel frame building.

Our factory is manufacturing high quality glazed tile roll forming machine, and regularly exported to Australia, USA, Thailand, Canada, Colombia, Philippines, Malaysia, Zambia, Angola, Saudi Arabia ect.

2. Technical details of glazed tile machine:

Machine Specifications

Weight About 4.5tons

Size About 5000*800*1200mm(length x width x height)

Color Main color: blue or as your requirement

Warning color: yellow

Suitable Raw Material

Material Galvanized Steel Coils

Thickness 0.3-0.8mm

Yield Strength 235Mpa

Main Technical Parameters

Quantity of forming rollers stations 15 stations

Diameter of forming rollers shafts 80mm

Roll Forming Speed 3-5m/min

Forming rollers material No.45 steel, coated with chromed treatment

Cutter material CR12 mould steel, with quenched treatment

Controlling system PLC and Converter

Electric Power requirement Main motor power: 4kw

Hydraulic unit motor power: 3kw

Electric voltage According to customer’s requirement

3. Main components of glazed tile roll forming machine

Decoiler 1 Set

Guiding Equipment 1 Set

Roll Forming Unit 1 Set

Post Cutting Unit 1 Set

Hydraulic Station 1 Set

PLC Control System 1 Set

Reveiving Table 1 Set

4. Production Flows

Uncoiling the sheet—Infeed guiding–Roll forming—Rectifying the straightness—Measure length—Cutting the panel–panels to the supporter (option: automatic stacker)

5. Advantages

1. About quality inspection: we have a quality inspection supervisor, he has 9 years of quality inspection experience, he is responsible for raw material inspection, control and finished machine quality

2. We have industrial waterproof and moisture-proof packaging cloth to prevent the humid air in shipping from corroding some parts of the machine

3. We provide 1 year warranty for the machine and provide lifetime service

6. Application

This machine is widely used in the production of the roof sheet and wall sheet and others.

7. Product photo

8. FAQ

Q:Can you customized our profile?

A:Yes dear.Our company have more than 25 years exoerience,5 engineers with more than 20 years experience design your profile.

Q:How can I trust you that machines pasted testing running before shipping?

A:1) We record the testing video for your reference. Or,

2) We welcome you visit us and test machine by yourself in our factory.

Q:What is your payment terms?

A:30% as the deposit by T/T in advance,70% T/T as balance after you inspect the machine before shipping.

We also accept 100% L/C at sight

We can accept Western Union payments.

Other payment terms you want to pay, please let me know and i will check and reply you.

Q:When will you delivery thye machine after i place the order?

A: After we get down payment,we will arrange production.About 30-45 days for delivery.

Q:What will you do if the machine broken?

A:We provide 12 nonths free warranty and free technical support for the whole life of any machine.

If the broken parts can’t repair,we can send the new parts replace the broken parts freely.If it is beyond the warranty period,we can negotiable to solve theproblem,and we supply the technical support for the whole life of the machine

Welcome to visit us!