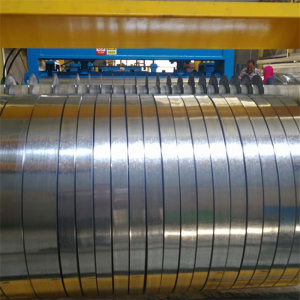

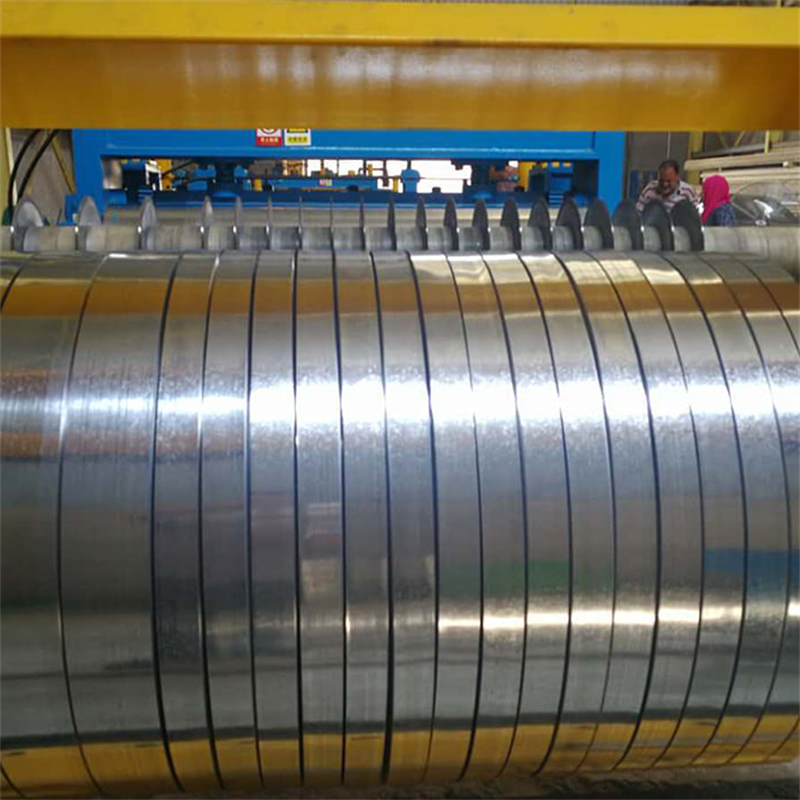

Factory Price High Speed Precision Steel Coil Steel Strip Slitting Machine Production Line

Machine Pictures

Description

A steel coil slitting line is usually referred to as a slitting line or a sheet cutting line. It is a metal-processing line where a wide sheet steel coil is slit into narrower or shorter straps. Though called a steel coil slitting line, such a processing line is sometimes used to process sheet metal coils other than steel. That said, stainless steel is the most common material a slitting line processes. The shorter or narrower steel straps will go into other metal-processing lines to produce the end products.

Because the thickness of the raw material is different, the yield strength is different, and the profile profile is different, these factors affect the configuration of the machine is different, so if you want to customize a sitting line, please send me your raw material, the thickness of your material, yield strength, etc., so that our engineers can help you customize the right machine according to your requirements.

Technical Details

|

Bending Machine Specifications |

|

| Weight | About 10 tons |

| Size | About 35000x7500x2000mm according to your profile |

| Color | Main color: blue or as your requirement |

| Warning color: yellow | |

|

Suitable Raw Material |

|

| Material | Galvanized Steel Coils, Color steel |

| Thickness | 0.3-3mm |

| Yield Strength | 235Mpa |

|

Bending machine Main Technical Parameters |

|

| Controlling system | PLC and button |

| Electric Power requirement | Main motor power: 80kw |

| Hydraulic unit motor power: 15kw | |

| Electric voltage | According to customer’s requirement |

Main Components

|

No |

Name |

Quantity |

|

1 |

Entry coil car |

1 |

|

2 |

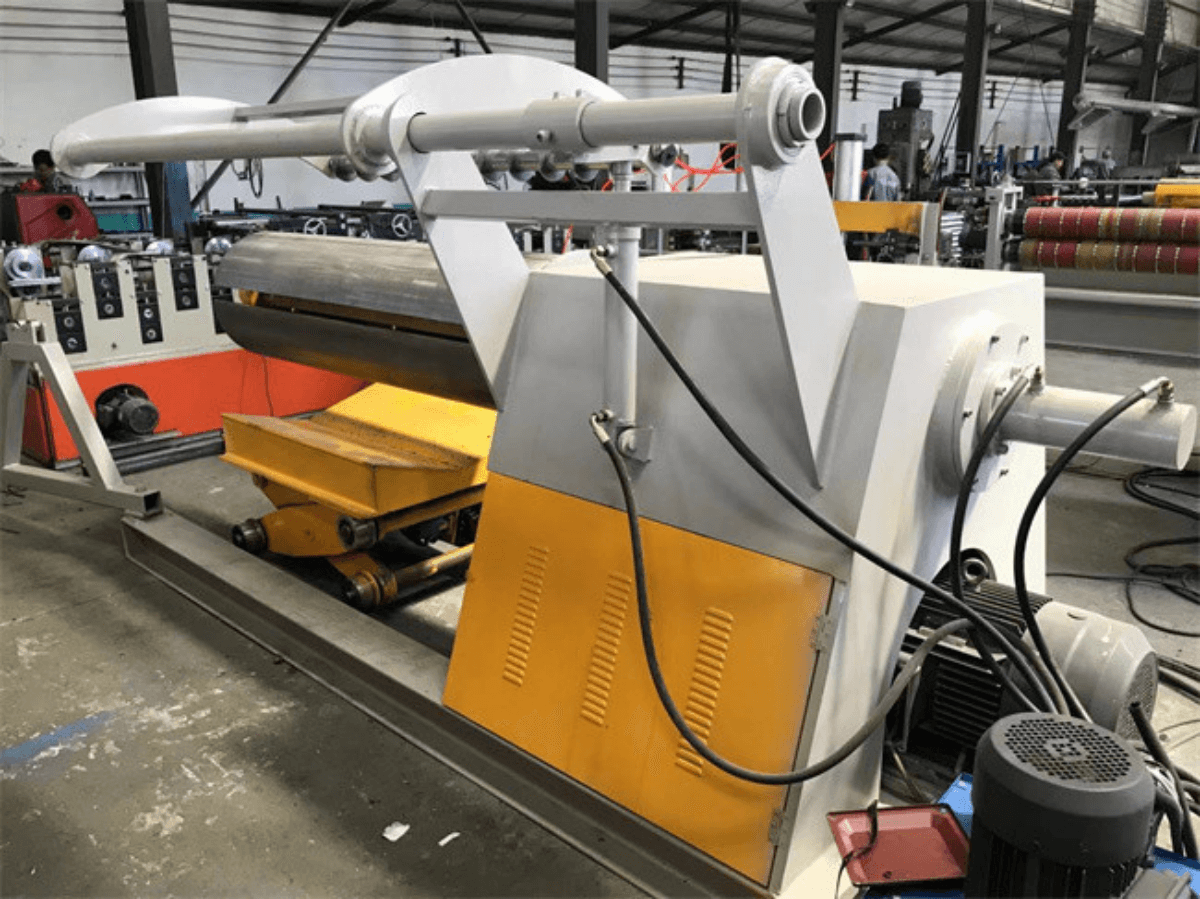

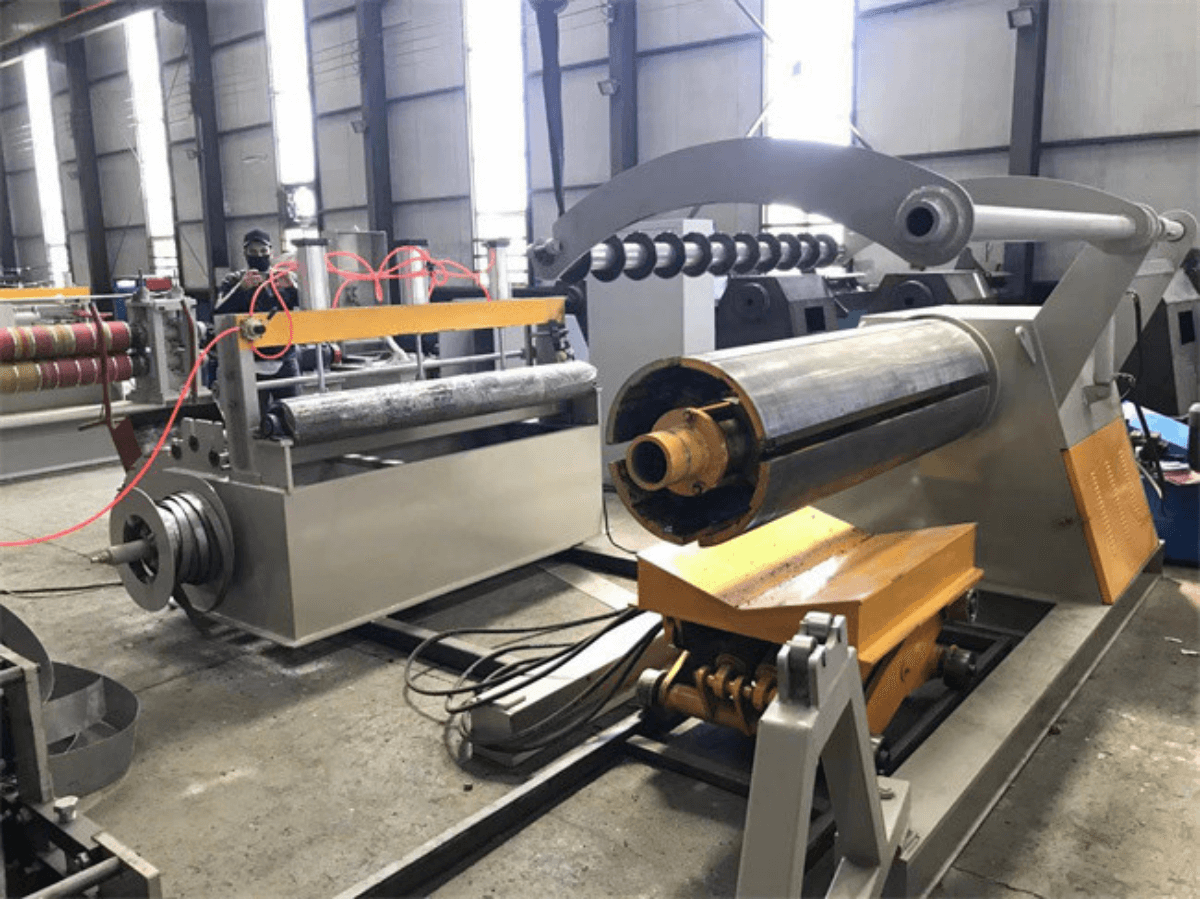

Hydraulic Decoiler |

1 |

|

3 |

Press and pinch device |

1 |

|

4 |

Hydraulic cutter |

1 |

|

5 |

Anti-Tracking Device |

1 |

|

6 |

Slitter |

1 |

|

7 |

Scrap winder |

1 |

|

8 |

Tension stand |

1 |

|

9 |

Recoiler |

1 |

|

10 |

Exit coil car |

1 |

|

11 |

Hydraulic system |

1 |

|

12 |

Electrical system |

1 |

Advantages

· Germany COPRA software design

· 5 engineers with more than 20 years experience

· 30 professional technician

· 20 sets advanced CNC production lines on site

· Passionate Team

· Installation engineers can reach your factory within 6 days

Application

This machine is widely used in a wide sheet steel coil is slit into narrower or shorter straps.

Product Photo

FAQ

Q: If need technician to workshop to debug and teach, how to do?

A:We provide online instruction, or We sent technician to your factory. Buyer should bear cost including: visa, round trip ticket and suitable accommodation, also buyer should pay the salary 100 USD/day.

Q. Can you provide OEM service for roll forming machine?

A: Yes, most of cold roll forming machine need to be customized as detailed request, because raw material , size , production

usage, machine speed, then machine specification will be some different.