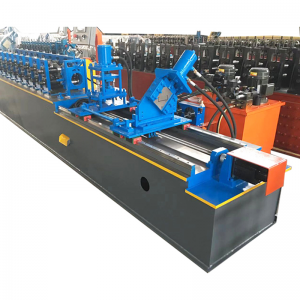

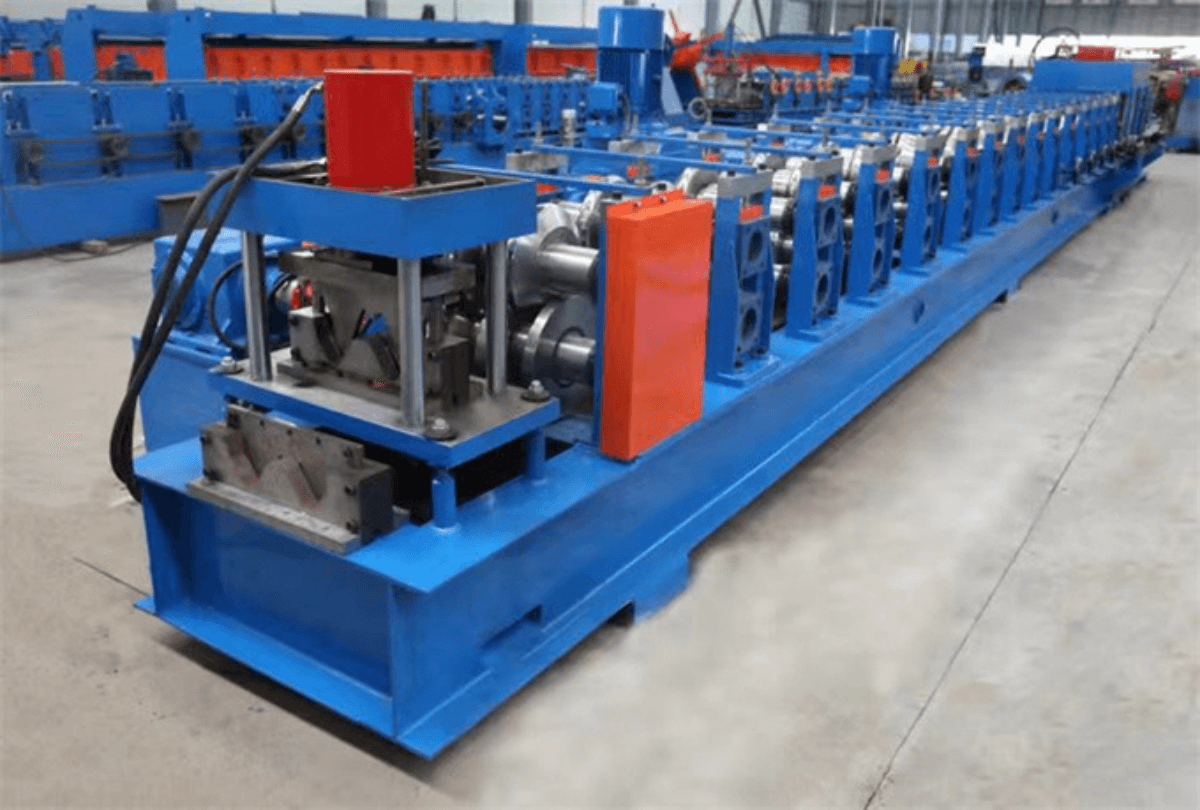

Blue Color Full Automatic 2 Waves High Speed Highway Guardrail Roll Forming Machine

Machine Pictures

Description

We are a professional highway guardrail roll forming machine manufacturer, It’s also named Crash guardrail Forming Machine, highway guardrail roll forming machine steel production line.

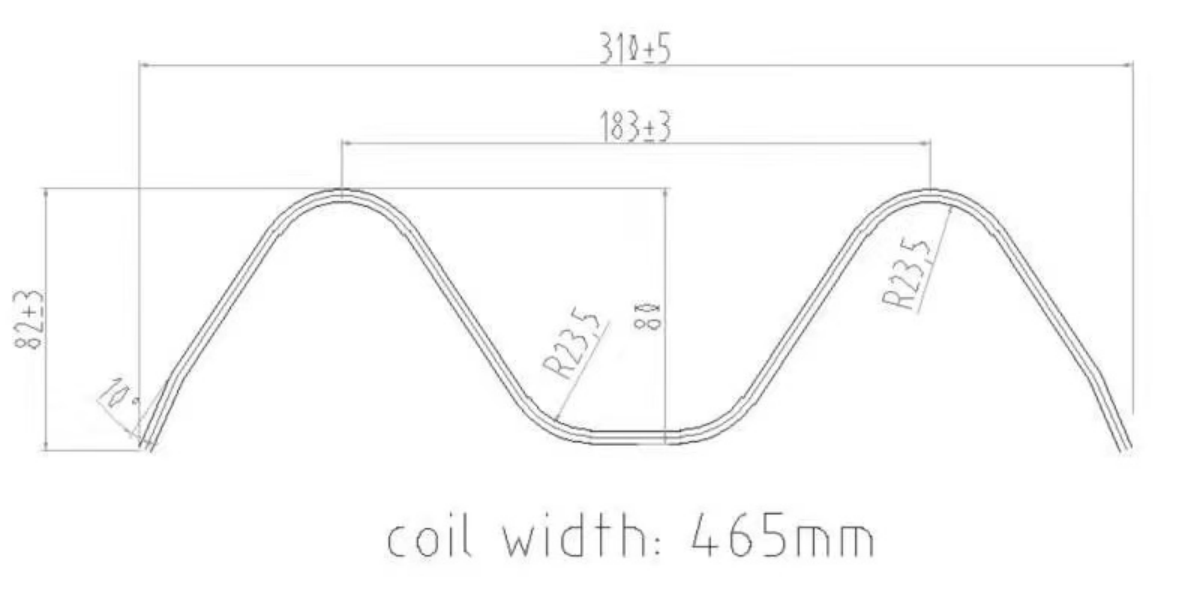

Our High Speed Cold Steel Two Peaks Three Waves Highway Guardrail Roll Forming Machine produce high quality w beam guardrail, one product machine can produce products of a wide rang of specifiations. highway 2 wave and 3 wave guardrail is the most popular.

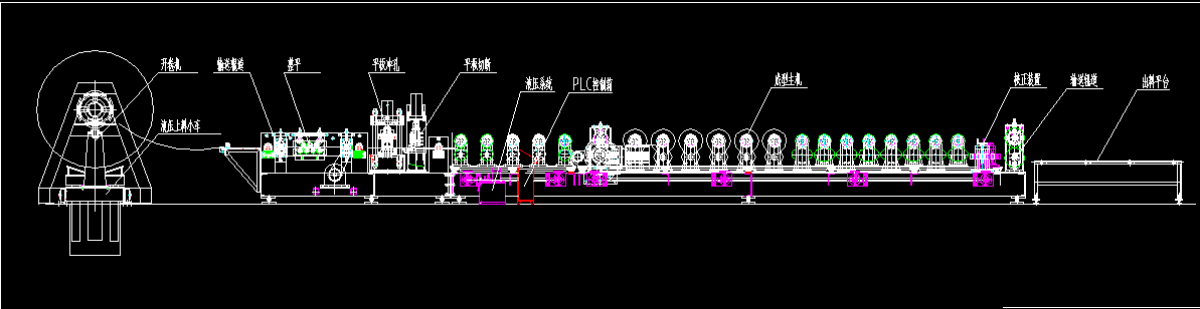

Production Flows

Decoiler → feeding table (sheet metal is put by guiding platform) → main forming machine → Hydraulic cutting system → Receiving table

Technical Details

| Material: Steel Strips | |

| Equipment operation | Automatically |

| Voltage | AC380/50Hz or at buyer’s requirement. |

| Thickness of sheet(mm) | Within4mm |

| Productivity | 8-9m/min |

| Diameter of shaft | 95mm |

|

Dimension of main structure(mm) Theoretical data for design |

13500mm*1600mm*2000mm |

| Weight | 24000 KGS |

| Material of rollers | GCR15, quenching and chroming |

| Total power(kw) | 66KW |

| Power of hydraulic system | 22KW |

| Power of main molding core | 22kw+22KW(cycloidal planetary gear speed reducer) |

Main Components

|

Manual Decoiler |

1 Set |

|

Feeding Table |

1 Set |

|

Roll Forming Unit |

1 Set |

|

Post Cutting Unit |

1 Set |

|

Hydraulic Station |

1 Set |

|

PLC Control System |

1 Set |

|

Reveiving Table |

1 Set |

Automatic Hydraulic Decoile can bear 5 tons

Usage:It is used to support the steel coil and uncoil it in a turnable way. The steel coil is uncoiled by Computer Cabinet.

Inner diameter: 450-508mm

Can bear the max width of the coil is 600mm

Can bear the max tons is 5 tons

Size of it is 1700mmx1500mmx1000mm

Feeding platform with pre manual cutter

Put the raw material(steel plate) through the beach to manufacture and process, it can guarantee that the products are neat, parallel and everything is uniformity. Please refer to the equipment regulation to know the function of locate angle iron.

Main molding core

In order to keep the product shape and precision, adopts welded sheet structure, motor reducer drive, Gear box transmission, roller surfaces polishing, hard plating , heat treatment and galvanizational treatment . The polished surface and the heat treatment towards the molds also can keep the molding plate surface smooth and not easy to be marked when it is being stamped.

Material of rollers:45# steel, surface hard chromium plating.

Main power: 22kw+22KW(cycloidal planetary gear speed reducer)

The machine bed we used 400m H Steel and machine body is 45mm thickness of the steel plate

Hydraulic system

It is controlled by gear wheel oil pump. After filling the hydraulic oil into the hydraulic oil tank ,the pump drive the cutter machine to begin the cutting job.

Components: The system includes a set of hydraulic tank , a set of hydraulic oil pump, two hydraulic pipes.and two sets of electromagnetism valves.

Power:22 kw

For let the hydraulic station can working long time, we install one wind fan cool systerm ,

Automatic shearing system

It adopts the hydraulic drive and automatic location to decide the dimension and cut the target products.

Material of blades: Cr12,quenching treatment

Components:It contains one set of cutting tools, one hydraulic tank and one cutter machine.

Computer control system

It adopts Delta PLC to control. The target piece`s length is adjustable and digit of it can be adjusted. Computed mode has two modes: automatic and manual one. The system is easy to operate and use.

PLC is Delata, Inverter is Delta, the other Electron component is Schneider.

High-precision automatic counter

One counter gauges length, pulses, and decides length. Omron made in Japan.

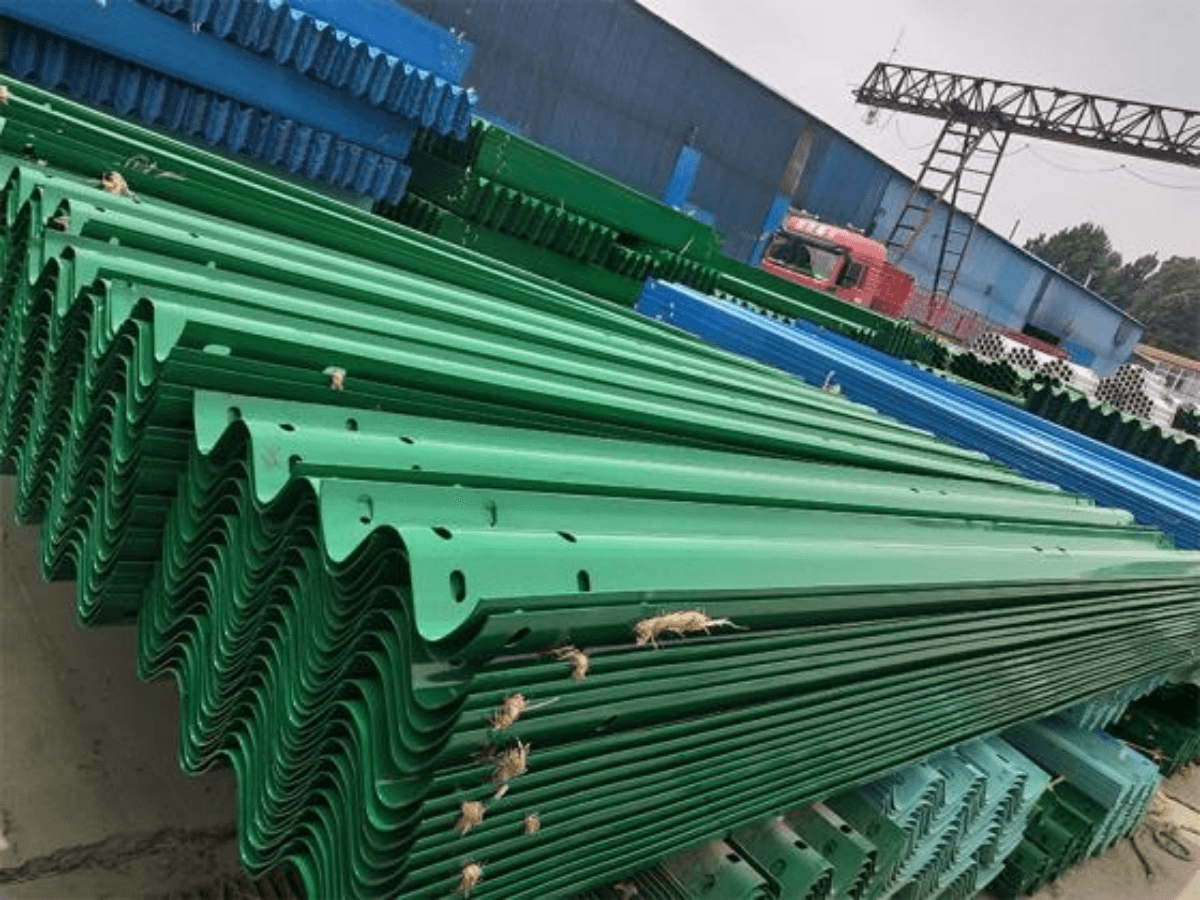

Product Photos

Our Highway Guardrail Roll Forming Machine

· More than 10 engineers and More than 10 designers with more than 10 years experience

· We have completed production system. And have high precious CNC grinders and milling machines,to make the rollers and shafts of the machine.

· Our machine's warranty period is 12 months and and we supply the technical support for the whole life of the equipment.

· We have professional engineer to check the quality of all parts. we do every step carefully to make sure the quality.

Application

This machine is widely used in the production of the metal roof sheets and wall panel.

Our machines are exported to many countries: Rwanda, Thailand, Philippines, Dubai, USA, South Africa, Peru, Russia, Saudi Arabia, Malaysia, Indonesia, etc.

FAQ

Q. Will i receive a good machine ? Same with my wanted ?

A: Yes sir/Madam. We will do the machine according to your profile drawing . About the profile drawing, we will confirm with you again before producing your machine. Then, after the machine finished, we will test the machine and guarantee the machine you received is a good machine. Because after you satisfied with the machine, and then you pay balance.

Q. What will you do if the machine is broken?

A: We provide 18 months free warranty and free technical support for the whole life of any machine. If the broken parts can't repair, we can send the new parts replace the broken parts freely, but you need pay the express cost by yourself. If it is beyond the warranty period, we can negotiate to solve the problem, and we supply the technical support for the whole life of the equipment.

Q. What is your payment terms?

A: 1 : We accept 30% T/T as deposit and 70% T/T as balance before shipping.

2 : We accept 100% L/C at sight

3: We accept Western Union payments.

4: Other payment terms you want to pay, please let me know and i will check and reply you.