The tile press should take into account the cutting efficiency, economy and processing cost under the premise of ensuring the processing quality. First, determine the amount of back cut according to the allowance after rough machining; second, select a smaller feed rate according to the roughness requirements of the processed surface; finally, select a higher cutting speed as much as possible under the premise of ensuring tool durability .

Determination of cutting amount Cutting amount includes cutting depth (cutting amount), spindle speed (cutting speed), and feed rate. For different processing methods, different cutting parameters need to be selected, and should be programmed into the program list. The principle of reasonable selection of cutting amount is: during rough machining, tile presses generally focus on improving productivity, but economy and processing costs should also be considered. Restrictive conditions, etc., select the feed rate as large as possible; finally determine the best cutting speed according to the tool durability. During semi-finishing and finishing.

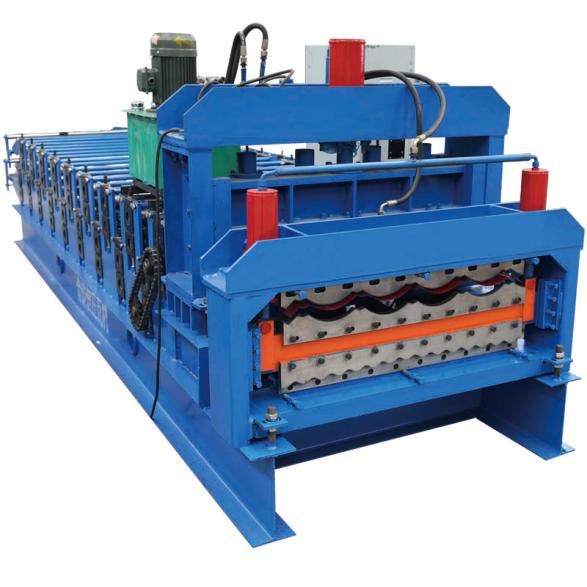

Analysis of props selection for tile press equipment processing machine tools:

When down milling is used, the machine tool of the tile press equipment is first required to have a gap elimination mechanism, which can reliably eliminate the gap between the table feed screw and the nut, so as to prevent the vibration generated during the milling process. It is ideal if the table is driven hydraulically. CNC machine tools generally use down milling, and manual milling machines generally use up milling. Secondly, it is required that there is no hard skin on the surface of the workpiece blank, and the process system of the machining center must have sufficient rigidity. If the above conditions can be met, the tile press with down milling should be used as much as possible.

Post time: May-18-2023