Technical trends of intelligent transformation of tile press equipment and machine tools:

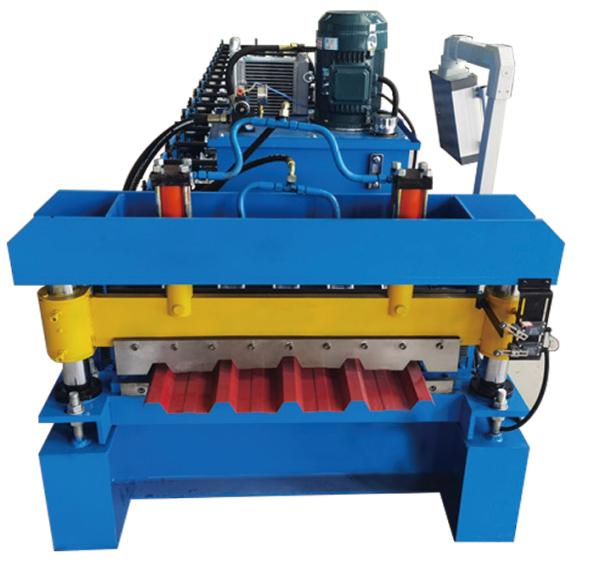

The tile press equipment has a reasonable structure, convenient operation, and complete functions, including feeding, pressing, glue dropping, heating, trimming, slotting, and cutting to form panels. It adopts precision low-speed metering pump, frequency conversion speed regulation, (or stepless speed regulation), computer control, and accurate measurement. High-level automatic control software is adopted to realize production information management. The entire unit automation control system adopts a highly integrated network, which makes the performance of the automation system more superior. It also has the advantages of easy operation, maintenance, maintenance, mechanical debugging, and easy mold replacement. Easy to operate. It can be installed and used alone, but manual billet loading and unloading is required. It can also be equipped with automatic loading rack and billet unloading manipulator, extruder, tile cutting machine, billet feeding machine and tile holder conveyor line to form color steel equipment for tile billet production. The assembly line does not require manual operation at all.

Intelligent monitoring of maintenance status. In order to reduce the load of maintenance work, it is necessary to have a system to take countermeasures before major failures occur, so it is very important to constantly monitor the maintenance status. It can be said that it is a future task to accumulate the historical data of the working state of the machine tool, predict the life based on this, and detect the life under the working state.

Intelligence to ensure safety. The latest intelligent technology to ensure safety can be said to be collision avoidance technology. Through the program, the interference check can be carried out during the movement and during the preparation work. The process requirements of typical parts are mainly the structural size, processing range and accuracy requirements of the parts. According to the accuracy requirements, that is, the dimensional accuracy, positioning accuracy and surface roughness of the workpiece, the control accuracy of the CNC lathe is selected. Choose according to reliability, reliability is the guarantee to improve product quality and production efficiency. The reliability of CNC machine tools means that when the machine tool performs its functions under specified conditions, it can run stably for a long time without failure. That is, the mean time between failures is long, and even if a failure occurs, it can be restored in a short time and put into use again. Choose a machine tool that has a reasonable structure, excellent manufacturing, and has been mass-produced. Generally, the more users there are, the higher the reliability of the CNC system is.

Post time: May-15-2023